Types of antifoul paints

Antifoul paint is a protective paint applied to the bottom of a boat, which keeps the hull clean, improves fuel efficiency, and prevents the growth and spread of non-native species.

Many antifoul paints use biocides, ingredients like zinc and copper. Whilst they are effective in preventing barnacles, slime, and weeds from attaching to a vessel, these ingredients can be harmful to the environment.

When antifoul paint is chipped through leeching or during application or removal it can enter the water, causing marine life to mistakenly ingest it. This results in a negative impact on the food chain.

Current antifouling products

When choosing an antifoul paint, it’s important to understand its impact on marine life and how this can be reduced.

Ablative/self-polishing biocidal coatings are applied annually in the form of a soft coating that “ablates” or slowly falls off. In turn, much of the coating finds its way into the water throughout the year. If remaining layers are jet washed in preparation for over coating without using a bunded washdown facility, excess paint will enter the water during maintenance.

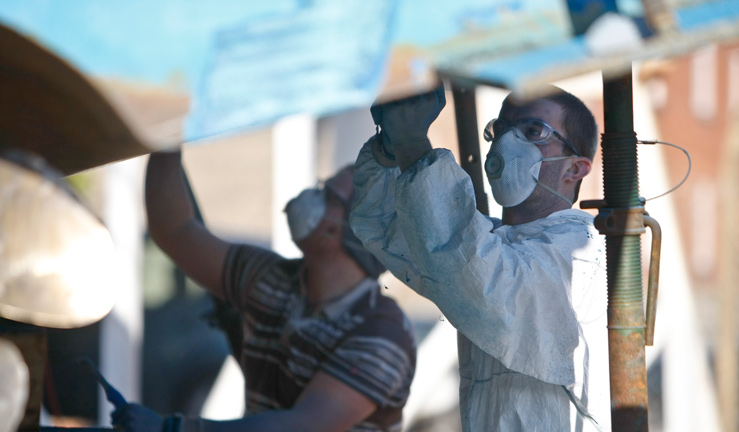

Following the Protect, Collect and Dispose method you can ensure that any debris or paint drips are captured by laying down a ground sheet before work begins.

An advantage to biocidal coatings is their low annual cost and DIY accessibility. However, proper protective clothing including suitable masks should always be worn and care taken to prevent them entering the water.

Hard coating antifouls are mostly used for racing boats. They require more preparation for annual re-coating such as sanding down or cleaning and are designed to give a smooth finish. Much like ablative coatings, preventative measures are needed to avoid water contamination.

Long-life Coats such as copper are still biocides but are designed not to ablate or be annually over-coated. Copper coats can last upwards of 10 years and their slow release hugely reduces pollution and harm to marine organisms over time.

It is recommended that these coatings are applied professionally. The application conditions need to be right for the coating to last. While it is possible to seal any existing antifoul layers, it is recommended that the hull grit be blasted back to the original substrate and applied from there.

Despite a high up-front cost, over a 10-year period the costs are comparable to soft coatings.

Foul Release Coatings such as silicone, are designed to be slippery rather than poisonous. Any growth falls off if the boat is moving at more than 7-8 knots or can simply be wiped away with a soft cloth.

Those who use this material report good results, particularly on high-speed crafts. The coating is harmless to marine life, however, if damaged its plastic can enter the water and will remain in the environment for a considerable time.

Coatings should be applied professionally. While it is possible to seal existing antifoul layers, it is recommended that the hull be grit blasted back to the original substrate and applied from there. While up-front costs are higher than ablative coatings, longevity of the coating mitigates initial costs.

Ultrasound has been used to deter growth on larger ships and is now available for smaller vessels. It is important to have a professionally specified system, as the transmission of ultrasound waves through steel is well understood. However, successful use with softer materials like wood and fibreglass requires careful design.

While ultrasound is low power, a constant power supply is needed for it to be effective. Manufacturers also recommend it be used in conjunction with a hard antifoul coating.

The biometric approach includes finsulate, which is designed to mimic the surface of sea urchin shells, that naturally deter algal growth. The material comes in the form of sheets that are glued to the hull, and the resulting surface is like a short-cropped nylon carpet.

New antifouling products

Recent introductions to the market seek to reduce environmental harm even further.

The hull Defender uses a foul release approach with a hard base, to improve longevity. The manufacturer claims this product is completely non-toxic and can be applied by anyone. Its objective is to hide a vessels surface, preventing marine organisms from seeing and attaching to it.

A new product developed in the biomedical sector is also of particular interest. It was founded in the non-toxic coatings used for replacement heart valves to stop unwanted matter sticking to them. Its developers also state that volumes needed to cover a boat would be extremely low at 2 litres for a 40’ boat.

We strongly recommend boaters move away from biocidal coatings, to reduce pollutant deposits on land and in the waters around our marinas, clubs, and centres.

For more information on antifouling best practice, or for further tips on sustainable boating, visit The Green Blue.